Regardless of whether we are aware of it, many companies practice vertical integration at one point or another. In fact, some of the most popular businesses in the world have gained control over the production and distribution of their products through vertical integration.

Recommended

In this article, we’ll define vertical integration, go through the two different strategies for accomplishing it, compare it to horizontal integration, list vertical integration’s advantages and disadvantages and provide some real-life examples of the process.

What is vertical integration?

When an organization or company controls one or more of the stages in the production process, it is called vertical integration. Also known as the supply chain, the production process refers to the transformation of raw materials into finished goods, which are then made available to the customer. There are four primary phases of the supply chain:

-

Raw materials, also known as commodities

-

Production

-

Distribution

-

Retail

A company has vertically integrated when they gain control over several of these stages of production. This often involves one company purchasing another company, such as a retailer, distributor or supplier, that is involved in the supply chain of the same market or industry.

Generally, companies that vertically integrate try to gain control over the supply chain stage that is either directly before or directly after their place in the production process. Companies choose to vertically integrate for many reasons, including:

-

Access to new channels of distribution

-

Reduced manufacturing costs

-

Reinforced supply chain

-

Increased profits

-

Increased production efficiency

-

Decreased distribution delays

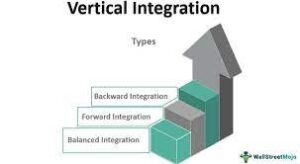

Types of vertical integration

There are two major ways for a company to gain control of multiple facets of the supply chain and effectively vertically integrate:

Forward integration

Forward integration refers to when a company gains control of a stage that is farther along in the production process, also known as downstream. For example, the organization may assume control over the post-production process by handling their own distribution or opening their own retail store. This increases the organization’s profitability by removing the need for intermediary companies.

Backward integration

Backward integration is when a company takes control of a stage that precedes theirs in the production process, also referred to as upstream. For example, a retailer may purchase a company that handles the manufacturing of its product.

Vertical integration vs. horizontal integration

Both vertical and horizontal integration are strategies that businesses use within their production process or industry. As we’ve already mentioned, vertical integration refers to when a company gains control of a supply chain stage that is either up or downstream from them in the production process.

Horizontal integration, on the other hand, is when a company gains control over an organization that is of equal value and level in the same industry. Horizontal integration takes place for several reasons, including:

-

Access to new markets or customers

-

Eliminating the competition

-

Increased company size

-

Diversified services and products

-

Increased profitability

-

Decreased costs spent on things like distribution, production and marketing

Horizontal integration eliminates competitors, which is great for companies. However, it also means that consumers have fewer available options within that market. This can lead to what is known as a monopoly, which is when one company controls the supply, prices and availability of services and products in a specific industry. In the United States, anti-trust laws have been established to protect consumers and prevent the existence of monopolies.

Advantages of vertical integration

Companies choose to vertically integrate for many reasons. There a number of advantages for vertical integration, such as:

-

Reduction of manufacturing costs: Without the need for inflation, a company can cut its costs for production and distribution by keeping it in-house.

-

Ability to access new channels of distribution: The ability to distribute its own products allows a company to reach new markets.

-

Increased production efficiency: Vertical integration means that there are fewer delays and mistakes as the products exchange hands.

-

Decreased costs due to economies of scale: This refers to the decrease of per-unit expenses by being able to buy raw materials in bulk or by streamlining the production process.

-

Increased profits: Lowered production and distribution costs lead to increased profitability for the company.

-

Decreased distribution delays: Distribution becomes more efficient without the use of a third-party company.

-

Development of a more competitive marketplace: Companies that vertically integrate can offer their products at lower prices, providing a more competitive marketplace for the consumer.

Disadvantages of vertical integration

Though vertical integration can be extremely beneficial for a company, there are some disadvantages, such as:

-

Increased expenses and debt

-

Inability to follow consumer trends by producing products away from their manufacturing plants

-

Split focus due to essentially running multiple businesses

-

Divisive company culture

-

Increased probability for mismanagement

-

Lack of expertise in the acquired production process

Examples

Here are some examples of vertical integration and their advantages:

Example 1

A large retailer is can offer its own store brands because it has taken control of production and distribution while maintaining control over the retail. This allows the company to manufacture products that are similar to the brand name offerings but at a more competitive price.

Example 2

A company that manufactures shoes decides to open its own flagship retail store that offers more product choices than you can purchase from a traditional retailer. They have also decided to open an outlet store that sells discounted products from previous seasons. Instead of having to visit a traditional retailer, consumers can visit these stores for more brand options and at decreased prices.

Example 3

A streaming service that provides access to TV shows and films from major studios has decided to begin creating original content. Now they can supply customers with films and shows among their own original content.

Example 4

A company that develops cutting-edge technological devices for consumers has decided to vertically integrate upstream by purchasing the manufacturers and laboratories that create their devices. This has provided them with the freedom and flexibility to research and create new products. Though they now have control over areas of production, they still have suppliers for the raw materials necessary for manufacturing.

Example 5

That same tech company has also vertically integrated downstream by opening and purchasing retail stores that exclusively sell their products. This allows them to control their distribution as well as their manufacturing and provides consumers with a place that they are guaranteed to find the product that they are looking for.